Marine Laser Cleaning Services Division

Marine Laser Cleaning

National Laser Restoration Provides

Hull Cleaning

Laser cleaning can be used to remove barnacles, algae, rust, and marine growth from the ship’s hull. This process improves fuel efficiency by reducing drag in the water and helps to maintain the structural integrity of the hull.Lasers are effective on all hull materials including.

- Steel

- Aluminum

- Wood

- Fiberglass

Rust and Corrosion Removal

Over time, ships are exposed to harsh saltwater environments that accelerate rust and corrosion. Laser cleaning is a precise, non-abrasive solution that removes rust without damaging the underlying metal, helping to extend the lifespan of the vessel.

Paint Removal

Removing old paint from marine vessels is necessary before applying fresh coats. Laser cleaning can strip away paint without the use of chemicals or abrasive materials, ensuring a cleaner and more environmentally friendly process.

Propeller Cleaning

Propellers often accumulate marine growth, which can reduce the vessel’s performance. Laser cleaning is an efficient way to clean propellers without disassembling them, maintaining their performance and lifespan.

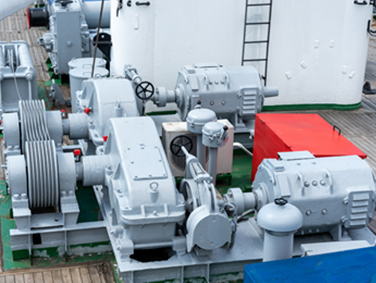

Ship Interior Cleaning

Inside ships, laser cleaning can be used to clean and maintain engine rooms, machinery, and other areas where contaminants, grease, and rust may accumulate. The process is precise enough to handle delicate components without risk of damage.

Deck and Superstructure Cleaning

The decks and superstructures of ships also require periodic cleaning to remove contaminants like salt, rust, and marine growth. Laser cleaning offers a fast, non-abrasive solution that minimizes downtime and reduces the need for protective measures.

Weld NDT inspection Preparation

Laser cleaning is highly effective for ship weld inspection, especially in the maritime industry where welds need to meet strict quality and safety standards.

Shop Services

We provide comprehensive shop services, including convenient pickup and delivery options for all components and equipment

Environmental and Safety Benefits

- No Secondary Waste or Chemicals: Unlike traditional cleaning methods that use sandblasting or chemicals, laser cleaning does not produce secondary waste. Waste streams are limited to the materials removed. Vapor and particulate are captured by fume extraction.

- Minimal Downtime: Laser cleaning can be conducted while the ship is docked or in service, which minimizes operational downtime.

- Precision Cleaning: Laser technology allows for targeted cleaning, reducing the risk of damage to sensitive equipment or surfaces.

We take pride in offering cutting-edge services backed by professional expertise and certification. Our team is Class IV Laser Certified, ensuring the highest standards of safety, precision, and efficiency in every procedure we perform. Our technicians include former Naval Quality Assurance Inspector (QAI) , Subsafe Systems, USS Alabama SSBN 731

With advanced training and specialized knowledge, we deliver exceptional results tailored to your specific needs. Trust us for a safe, effective, and results-driven experience.

Call For a

Free Inspection

National Laser Restoration

- 14209 29th St. East STE 101-102, Sumner WA 98390

Steel

Wood

Aluminum

Fiberglass