Automotive

National Laser Restoration offers advanced laser cleaning

solutions tailored to meet the diverse needs of the automotive market, from classic car restoration to custom part fabrication. With our expertise in laser surface cleaning, we provide both

professional

cleaning services and state-of-the-art laser equipment sales and support. Whether you’re looking to restore and preserve vintage vehicles, prepare custom surfaces for coatings, or streamline manufacturing processes, our team is here to deliver efficient, eco-friendly solutions. Backed by a commitment to precision and quality, National Laser Restoration empowers automotive

professionals to achieve superior results, minimize downtime, and enhance overall productivity.

Classic Car and Hot Rod Restoration

- Paint and Rust Removal: Laser cleaning can strip layers of paint and remove rust without damaging the metal underneath. This precision is especially valuable in restoring classic cars, where preserving the original metal is crucial.

- Metal Polishing: The technology can be used to clean and polish components and other metal parts without abrasives, maintaining the original look and feel of the parts.

- Detail Work: Laser cleaning can selectively remove contaminants and corrosion from intricate areas, like grilles, emblems, and smaller parts that can be hard to clean manually.

Custom and Aftermarket Parts Fabrication

- Pre-Welding Surface Prep: For custom fabrications and parts, lasers can be used to clean surfaces before welding or joining parts, ensuring strong, clean welds without oxidation or debris.

- Surface Texturing for Coatings: For custom finishes, laser cleaning can help create an optimal surface for adhesion before applying paint or protective coatings, leading to a more durable finish.

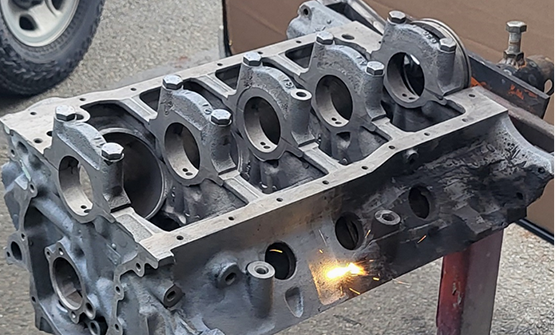

Engine and Mechanical Part Cleaning

- Oil and Grease Removal: Lasers can effectively clean engines, brake systems, and other mechanical components of oil, grease, and other contaminants without using chemicals or solvents.

- Restoring Internal Parts: Laser cleaning is precise enough to remove contaminants from internal parts (like cylinder heads and camshafts), aiding in repair and extending the life of critical components.

Production Line Efficiency for OEMs and Suppliers

- Tool and Mold Cleaning: In production, lasers can keep tooling and molds clean without downtime or abrasive methods, improving efficiency and product quality.

- Improved Adhesion and Bonding: Laser cleaning can prepare surfaces for adhesives, sealants, and coatings in manufacturing lines, ensuring these materials adhere more effectively and reducing defects.

Sustainability and Cost-Effectiveness

Sustainability and Cost-Effectiveness

Laser cleaning avoids the need for chemicals, abrasive materials, and excessive labor, making it an environmentally friendly solution that reduces waste and health hazards. Since it’s a contactless method, it also minimizes wear and tear on the underlying materials, which can help extend the life of parts and reduce repair costs over time. laser cleaning is a powerful tool for anyone from classic car restorers to auto manufacturers looking to improve both quality and efficiency in their operations.

Reach out to National Laser Restoration if you’d like more specific details for a presentation or materials.